WECO offers a variety of walnut moisture monitoring solutions. Select the one that best meets your unique needs.

Handheld Moisture Meter. This device, which requires a worker to get a manual reading from each bin, is a practical choice for the smaller processor.

Automated Moisture Meter. This unit consists of a series of devices that are installed in walnut bins. The moisture in each bin is displayed at a central location via computer.

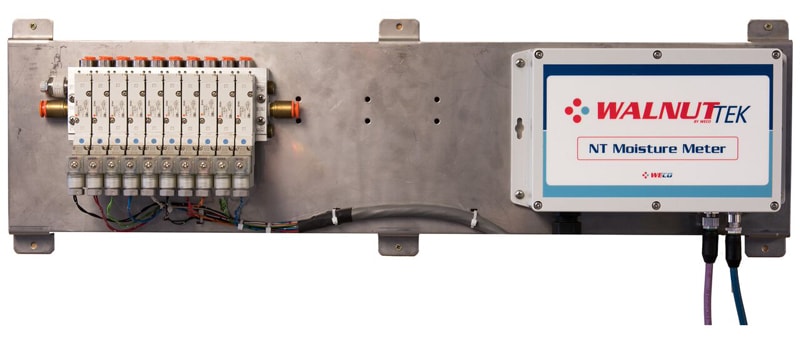

Automated Moisture Monitoring with Door Control. In addition to the benefits of the automated moisture meter, this option features control of the air doors, which allows hot air into the bins to dry walnuts to a preset moisture limit. This control is achieved via pneumatic cylinders that are actuated by an air valve.

When all bins (up to 20) in a single row are dried, the system shuts down the burner first and then the fan. This saves energy and fuel, while also preventing over-drying of the walnuts, which decreases weight and revenue.

Automated Moisture Monitoring with Door Control and Bin Fill. WECO’s most comprehensive offering includes automatic fill gate oversight along with moisture monitoring and control of the air doors. Instead of requiring a worker to watch bins as they fill, this device closes the gate automatically when the fill point is reached.